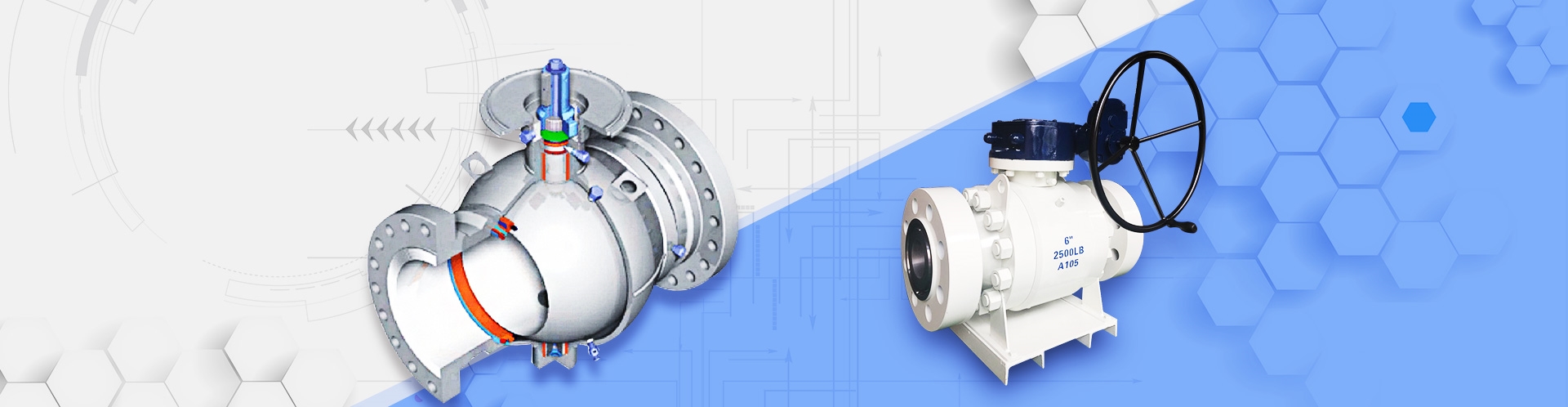

FYV’s floating ball valve is a valve with its ball floating(not fixed by a trunnion) inside the valve body; it drifts toward to the downstream side and tightly pushes against the seat under the medium pressure to ensure a reliable seal. The floating ball valve is a simple design with good sealing performance relying on the seat material to withstand the workload as the sealing pressure is barred by the seat ring.

Technical specification

Design & manufacturing standard as per ASME B16.34/API 6D/BS EN ISO 17292(BS5351)

Face to face standard as per ASME B16.10

Fanged ends standard as per ASME B16.5/ASME B 16.25/ASME B 16.11/ASME B 1.20.1

Testing & inspection standard as per API598/BS EN 12266(BS6755)

Fire-safe testing as per API 607/API 6FA

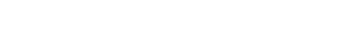

Product Range

Body material: Carbon steel, Stainless steel, Alloy steel ,Monel, Duplex, Inconel,etc

Size range(s):1/2"~6"

End Connection: RF, RTJ,BW, NPT,SW

Pressure rating: Class150 – Class1500

Working temperature: -46℃ - +200℃

Operation : wrench, lever,worm gear, electric, etc

Design Features

2-3 Piece Body

Anti-Static Device

Blow-out Proof Stem

Fire safe Design

Low Emission

Full bore and reduced bore design with the minimum flow resistance

Optional locking device

Optional ISO 5211 top flange