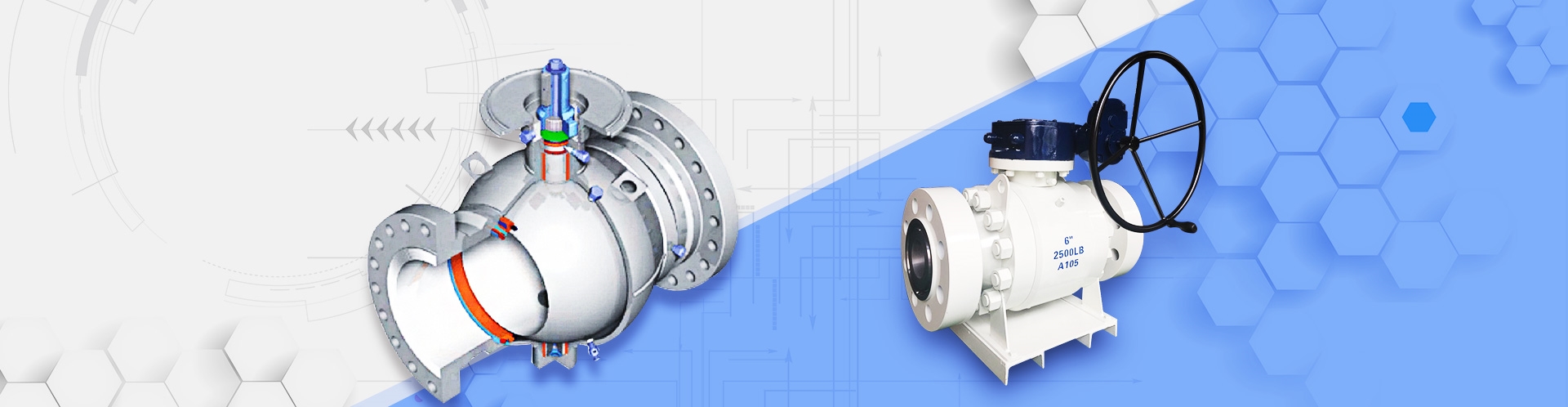

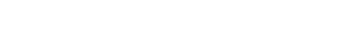

The fully-welded ball valve produced by FYV adopts forged material, welded body, instead of bolts and nuts, to avoid any potential leakage from body. FYV’s fully welded ball valve ensure sealing much more reliable. The valves can be spherical and cylindrical type. Usually the spherical type has only one welding seam on the body, the cylindrical type has two welding seam on the body.

Technical specification

Design & manufacturing standard as per ASME B16.34/API 6D/BS EN ISO 17292(BS5351)

Face to face standard as per ASME B16.10

Fanged ends standard as per ASME B16.25

Testing & inspection standard as per API598/BS EN 12266(BS6755)

Fire-safe testing as per API 607/API 6FA

Product Range

Body material: Carbon steel, Stainless steel, Alloy steel ,Monel, Duplex, Inconel,etc

Size range(s):2"~36”

Pressure rating:Class150~Class2500

End connection: BW

Working temperature:-46℃~+200℃

Operation:Wrench, worm gear, gear box, Electric-actuator , Pneumatic- actuator, etc.

Design Features

Simple structure with good tightness and small torque;

With a fully-welded valve body, full bore and the minimum flow resistance

Emergency sealant injection;

Cavity pressure self relief;

Fire safe, anti-static and anti-blowout stem design;

Valve seat function DBB, DIB-1, DIB-2;

Be able to be used for underground installation without corrosion of interior parts

Service life up to 30 years.